Premium 5 Ton Wheel Loaders from Trusted Manufacturers and Factories

The 5-ton wheel loader from Linyi Weiman Import and Export Co., LTD is engineered for exceptional efficiency and durability in construction and mining applications. Equipped with a powerful engine and a dependable hydraulic system, this wheel loader ensures high productivity while keeping maintenance costs low. Its ergonomic design minimizes operator fatigue during long working hours, prioritizing safety and comfort at the job site. Advanced technology enhances operational ease, allowing for quick and efficient use. Built with high-quality materials, this robust machine guarantees outstanding performance and longevity, even in the most demanding environments. For exceptional construction machinery that adheres to the highest industry standards, contact Linyi Weiman Import and Export Co., LTD today to learn more about our 5-ton wheel loader and its benefits for your business.

Quick Tips To Wheel Loader 5 Ton Service Service Backed by Expertise

When it comes to maintaining your 5-ton wheel loader, having expert advice can make all the difference in performance and longevity. At Linyi Weiman Import and Export Co., LTD, based in Shandong province, we understand the complexities of heavy construction equipment and are here to provide essential service tips backed by years of industry experience. Regular maintenance not only ensures optimal operation but also prevents unexpected breakdowns, saving you time and money on repairs.

Firstly, consider routine checks on hydraulic fluids and engine oil; maintaining proper levels prevents overheating and ensures efficient hydraulics performance. Additionally, inspecting tire pressure and tread wear can significantly enhance stability and fuel efficiency, critical in heavy-duty operations. It's also vital to clean air filters regularly, as clogged filters can reduce engine efficiency. Trustworthy suppliers like Weiman provide high-quality replacement parts and expert recommendations tailored to your operational needs.

Moreover, investing in a solid service plan is crucial. Weiman's extensive expertise in the construction equipment sector guarantees that you have access to the best support and products available. Our range of machinery, including luxury mini loaders and excavators, comes with the assurance of quality and reliability. By choosing Weiman, you not only get superior products but also the expertise to keep your machinery running smoothly, ensuring your projects are completed on time and within budget.

Quick Tips To Wheel Loader 5 Ton Service Backed by Expertise

| Service Task | Frequency | Estimated Time | Expert Notes |

|---|---|---|---|

| Oil Change | Every 250 hours | 1 hour | Use high-quality hydraulic oil for better performance. |

| Air Filter Replacement | Every 500 hours | 30 minutes | Check for dust accumulation regularly, especially in dry environments. |

| Brake Inspection | Every 1000 hours | 2 hours | Ensure the brake fluid is at the correct level and check pads for wear. |

| Tire Inspection and Pressure Check | Weekly | 15 minutes | Maintain recommended tire pressure for optimal fuel efficiency. |

| Battery Maintenance | Every 300 hours | 1 hour | Check terminals for corrosion and ensure a secure connection. |

The Secret to Wheel Loader 5 Ton Your Trusted OEM Partner More Than a Supplier - A Partner

P

Paige Foster

I love this product! The team provided excellent support and guidance.

25

June

2025

S

Samantha Wood

Truly impressed with the item’s quality and the after-sales service was superb.

28

June

2025

L

Layla Carter

Remarkable item! The support team was responsive and extremely professional.

18

May

2025

J

Julia Simmons

Incredible quality! I appreciate the professionalism of the after-sales service.

28

May

2025

R

Ryan Hudson

I highly recommend this product! Quality combined with excellent service.

09

May

2025

L

Luca Young

The quality of this product is impressive! The after-sales team was professional and very helpful.

17

June

2025

Wheel Loader

Wheel Loader

Excavator

Excavator

Motor Grader

Motor Grader

Backhoe Loader

Backhoe Loader

Road Roller

Road Roller

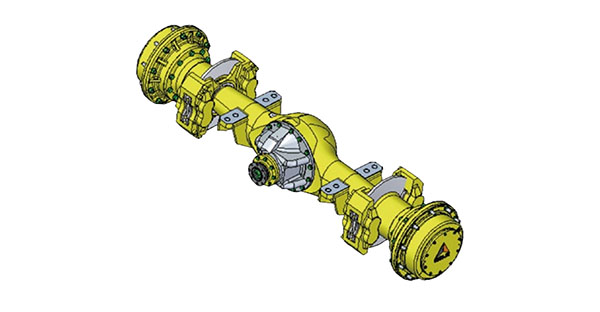

Spare Parts

Spare Parts