Premium Rear Drive Shafts from Trusted Manufacturers & Top Suppliers

With a focus on high-quality rear drive shafts, our offerings are designed to meet the rigorous standards of the automotive industry. As an experienced supplier and manufacturer, we are committed to delivering precision-crafted components that ensure durability and reliability for your machinery and vehicles. Whether you require replacements or bulk orders, you can depend on our rear drive shafts to perform optimally. Partnering with Linyi Weiman Import and Export Co., LTD. means collaborating with a team dedicated to understanding your needs and enhancing your satisfaction. Contact us to learn more about how we can support your supply chain requirements!

Key Methods For Rear Drive Shaft Custom Solutions, Your End-to-End Solution

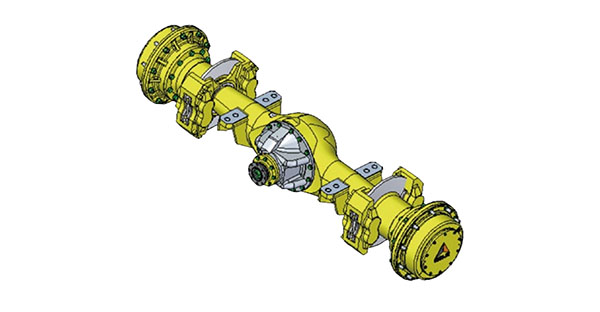

In the world of heavy construction equipment, the reliability and performance of machinery components play a crucial role in operational efficiency. One critical element often overlooked is the drive shaft, particularly in rear-drive systems. Custom solutions for rear drive shafts can significantly enhance the performance of loaders, excavators, and other heavy machinery. This blog discusses key methods for developing these custom solutions, emphasizing the importance of precision engineering and tailored designs that meet specific operational requirements.

Firstly, investing in advanced materials and manufacturing techniques is essential. Whether it’s utilizing high-strength steel or composite materials, these innovations ensure that drive shafts can withstand the rigorous demands of construction sites. Customization options may include variations in length, diameter, and coupling configurations, all aimed at optimizing the machinery's performance. Furthermore, leveraging simulation software can help identify potential stress points and design flaws early in the development process, allowing for more efficient solutions.

Finally, collaboration with clients is paramount. Understanding the unique challenges faced by each operation enables suppliers to create tailored solutions that enhance machinery functionality. Regular feedback loops throughout the production cycle can lead to innovative adjustments that ensure the final product aligns with the clients’ expectations. This end-to-end approach not only boosts equipment reliability but also strengthens partnerships within the global supply chain, ensuring that heavy machinery operates at peak performance under diverse conditions.

Key Methods For Rear Drive Shaft Custom Solutions, Your End-to-End Solution

| Method | Description | Applications | Advantages |

|---|---|---|---|

| Precision Machining | Using CNC technology to achieve tight tolerances and high-quality finishes. | Automotive, Aerospace, Industrial Machinery | Enhanced durability and performance; reduced vibration. |

| Material Selection | Choosing materials that provide the best strength-to-weight ratio and corrosion resistance. | Heavy-duty vehicles, Off-road applications | Increased longevity and reduced maintenance costs. |

| Dynamic Balancing | Balancing the drive shaft to minimize vibrations and improve efficiency. | High-performance vehicles, Racing | Improves ride quality and extends component life. |

| Custom Fabrication | Tailoring solutions to meet specific vehicle requirements and performance goals. | Custom vehicles, Modifications | Guaranteed fit and performance; unique solution. |

| Testing & Quality Assurance | Rigorous testing protocols to ensure reliability and performance standards. | All automotive applications | Meets industry standards; ensures customer satisfaction. |

Methods To choose Rear Drive Shaft Pioneers in the Field Guarantees Peak Performance

I

Isabella Brown

Incredible value for the quality provided! The after-sales service was quick and efficient.

14

June

2025

N

Noah Wilson

The item exceeded my expectations in quality. The team was very professional and attentive!

17

June

2025

A

Alexander King

Quality and service both exceeded my expectations! Highly recommended.

09

May

2025

S

Scarlett Hall

Impressive craftsmanship! The after-sales support team was very helpful and cooperative.

16

May

2025

J

Jayden Diaz

Impressive quality for the price! I appreciate the great after-sales service.

31

May

2025

S

Sophie Day

Exceptional quality! With such professional support, I felt valued as a customer.

12

May

2025

Wheel Loader

Wheel Loader

Excavator

Excavator

Motor Grader

Motor Grader

Backhoe Loader

Backhoe Loader

Road Roller

Road Roller

Spare Parts

Spare Parts