Top Heavy Equipment Manufacturers in China: Key Factory Insights and Innovations

Linyi Weiman Import and Export Co., LTD. stands as a premier manufacturer of solutions for heavy equipment movement. We specialize in designing, producing, and distributing top-quality machinery, including forklifts, cranes, and material handling machines. Our products are engineered to serve a variety of industries such as construction, logistics, and industrial sectors. Renowned for their durability, advanced technology, and exceptional performance, our machines are ideal for optimizing operational efficiency. With a strong emphasis on innovation and customer satisfaction, we continually enhance our offerings to adapt to market needs. Our skilled team of engineers and technicians ensures every piece of equipment meets rigorous standards through comprehensive testing before market release. Choosing Linyi Weiman Import and Export Co., LTD. means investing in reliable heavy equipment that elevates business productivity. Contact us to learn about our comprehensive range of solutions for heavy equipment movement.Best Practices For Heavy Equipment Movement Manufacturers Industry Giant Industry Leaders

In the ever-evolving landscape of heavy equipment movement, manufacturers are constantly seeking ways to enhance their operations while maintaining efficiency and safety. As an industry leader, Linyi Weiman Import and Export Co., LTD, located in Linyi city, Shandong province, exemplifies best practices in this domain, cementing its reputation as the top professional supplier of heavy construction equipment. With a robust portfolio that includes wheel loaders, luxury mini loaders, backhoe loaders, skid steer loaders, excavators, and motor graders, Weiman sets the standard for quality and innovation.

One of the best practices in the industry involves leveraging advanced technology to optimize equipment performance and safety. Automated systems and IoT integration can significantly streamline operations, reduce human error, and enhance the decision-making process. Weiman's commitment to incorporating cutting-edge technology into its machinery not only boosts productivity but also ensures compliance with stringent safety regulations, mitigating risks associated with heavy equipment movement.

Furthermore, fostering strong relationships with global procurement partners is essential. By understanding the unique needs of different markets, manufacturers like Weiman can tailor their offerings and provide exceptional customer service. This customer-centric approach not only drives sales but also builds long-term partnerships crucial for sustained growth in a competitive landscape. As global buyers continue to seek reliable and innovative suppliers, Weiman stands out as a trusted provider ready to meet the demands of the heavy equipment movement industry.

Best Practices For Heavy Equipment Movement Manufacturers

| Practice | Description | Benefits | Challenges |

|---|---|---|---|

| Regular Training | Conduct regular training sessions for operators on best practices and safety protocols. | Enhances safety, reduces accidents, and improves operational efficiency. | Time commitment and potential temporary downtime. |

| Routine Maintenance | Implement a schedule for regular maintenance checks on all equipment. | Prevents breakdowns and extends equipment lifespan. | Costs associated with maintenance and potential need for downtime. |

| Load Planning | Analyze and plan loads carefully to ensure safe and efficient movements. | Reduces risks of overload and enhances operational efficiency. | Requires time and expertise for accurate evaluations. |

| Technology Utilization | Use advanced technology for tracking and managing equipment movements. | Improves tracking accuracy and reduces manual errors. | Initial investment costs and training required for staff. |

| Safety Audits | Conduct regular safety audits to identify and rectify potential hazards. | Enhances overall safety culture and compliance with regulations. | Time-consuming and may expose vulnerabilities. |

How To Decide Between Heavy Equipment Movement Manufacturers in 2025 Supplier

J

James Parker

Fantastic product! The after-sales staff proved to be incredibly professional and went above and beyond to assist me.

10

May

2025

A

Amelia Hall

This product’s quality is remarkable! I admire the professionalism displayed by the support staff.

10

June

2025

A

Avery Thompson

Impressive quality! The customer service team demonstrated great expertise and support.

07

May

2025

W

Wyatt Hall

A quality product with excellent after-sales service. The team was very professional.

07

July

2025

S

Sophie King

Fantastic quality! The after-sales team really knows their stuff and provided great help.

03

July

2025

J

Jameson Taylor

Incredible item! The after-sales support staff was remarkable and very knowledgeable.

03

July

2025

Wheel Loader

Wheel Loader

Excavator

Excavator

Motor Grader

Motor Grader

Backhoe Loader

Backhoe Loader

Road Roller

Road Roller

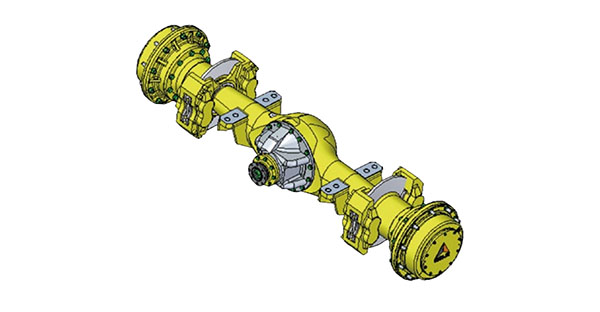

Spare Parts

Spare Parts