Heavy Equipment Monitoring Solutions from Leading Manufacturer in China for Factories

Enhance the efficiency and safety of your factory or construction site with our state-of-the-art heavy equipment monitoring system. Developed by Linyi Weiman Import and Export Co., LTD., this solution provides real-time insights into the performance and condition of your machinery. Our advanced technology tracks essential metrics, including fuel consumption, engine temperature, and equipment location, allowing companies to optimize operations and schedule preventative maintenance. The user-friendly system easily integrates with existing machinery, minimizing production disruptions and granting immediate access to crucial data. Linyi Weiman is dedicated to delivering innovative solutions that boost efficiency, productivity, and safety in the industrial sector. Contact us to learn how our monitoring system can enhance your operations.Insider Tips For Heavy Equipment Monitoring Factories Manufacturers You Can Rely On Pioneers in the Field

When it comes to sourcing heavy construction equipment, making informed decisions is paramount. Linyi Weiman Import and Export Co., LTD stands out as a reliable partner for manufacturers looking to optimize their operations. Located in Linyi city, Shandong province, Weiman specializes in a diverse range of machinery, from wheel loaders to luxury mini loaders, backhoe loaders, skid steer loaders, excavators, and motor graders. Our commitment to quality and innovation makes us pioneers in the field of heavy equipment monitoring.

Understanding the needs of global buyers is crucial. Weiman’s extensive experience in the industry allows us to offer insights that can help you navigate the complexities of procurement. Our heavy construction machines not only meet international standards but also come equipped with advanced monitoring systems that provide real-time data on performance and maintenance needs. This capability ensures that your operations remain efficient and cost-effective, allowing you to focus on growth while we handle the equipment you rely on.

As a forward-thinking supplier, Weiman works closely with manufacturers to tailor solutions that fit your specific challenges. Whether you're looking to enhance productivity or reduce downtime, we provide the tools and expertise necessary to achieve your goals. Our dedication to customer satisfaction and transparent communication makes us the go-to choice for businesses around the globe seeking robust construction equipment and reliable partnerships in the industry.

Insider Tips For Heavy Equipment Monitoring Factories Manufacturers You Can Rely On Pioneers in the Field

| Factory Location | Monitoring Technology | Key Benefits | Typical Equipment | Performance Metrics |

|---|---|---|---|---|

| North America | GPS Tracking & IoT Sensors | Real-time location tracking, predictive maintenance | Excavators, Bulldozers | Utilization rate, Downtime reduction |

| Europe | Telematics Systems | Fuel efficiency monitoring, operator behavior analysis | Crane, Forklifts | Fuel consumption, Load capacity |

| Asia | Remote Monitoring Software | Asset health tracking, alert systems | Loaders, Graders | Maintenance alerts, Equipment wear analysis |

| Australia | Machine Learning Insights | Predictive analysis, Operational efficiency | Dump Trucks, Pavers | Predictive maintenance intervals, Cost savings |

How To Pick The Right Heavy Equipment Monitoring Factories Where Service Meets Innovation Outperforms the Competition

D

Daniel Johnson

Excellent purchase! The support personnel displayed impressive expertise in resolving my inquiries.

04

July

2025

A

Alexander King

Quality and service both exceeded my expectations! Highly recommended.

09

May

2025

Z

Zoe Allen

I’m thoroughly satisfied! The product quality is exceptional, and service was impeccable.

23

May

2025

E

Elijah Green

Outstanding product! I was pleased with the professionalism of the customer support team.

14

May

2025

N

Natalie Scott

Great buy! The product quality truly stands out, and the service provided was excellent.

01

July

2025

M

Maya Rivera

Absolutely love this product! The after-sales service resolved my concerns quickly.

04

July

2025

Wheel Loader

Wheel Loader

Excavator

Excavator

Motor Grader

Motor Grader

Backhoe Loader

Backhoe Loader

Road Roller

Road Roller

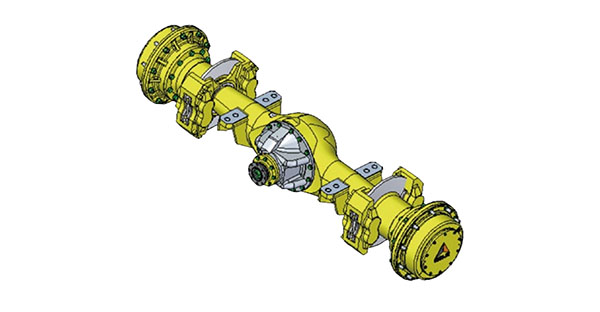

Spare Parts

Spare Parts