Premium Bearing Shells from China's Leading Wholesale Manufacturers & Factories

At our China Top Bearing Shell Factory, we offer premium bearing shells tailored to meet the unique requirements of various industries. As a committed manufacturer and supplier, our emphasis is on quality throughout the entire production process, ensuring each bearing shell is meticulously crafted. We leverage advanced technology and skilled craftsmanship to provide durable and reliable products. We collaborate closely with clients to create customized solutions tailored to specific applications. Whether you require bulk orders or unique designs, we are dedicated to meeting your needs. Partnering with Linyi Weiman Import and Export Co., LTD. ensures you have a trustworthy source for your bearing shell requirements. Our aim is to build lasting relationships founded on trust and satisfaction, supporting your business every step of the way. Together, we can achieve your objectives.Key Methods For China Top Bearing Shell Factory From Concept to Delivery Your Trusted OEM Partner

When it comes to sourcing high-quality bearing shells for construction equipment, partnering with a reliable OEM manufacturer is essential. In the dynamic landscape of the construction industry, efficiency and precision are paramount. From initial concept development to final delivery, understanding the key methods employed by top bearing shell factories in China can enhance procurement strategies for global buyers.

One crucial aspect is the emphasis on advanced technology and innovation. Leading manufacturers invest heavily in research and development to ensure their products meet international standards. This commitment enables them to deliver bearing shells that provide durability and optimal performance in heavy machinery. Additionally, effective supply chain management plays a significant role in maintaining timely deliveries. By employing streamlined processes and fostering strong relationships with suppliers, they can reduce lead times and ensure that buyers receive their orders when needed.

Quality control is another cornerstone of successful manufacturing. Top factories in China implement rigorous testing protocols throughout the production process to guarantee that every bearing shell meets stringent quality benchmarks. This attention to detail not only builds trust with clients but also minimizes the risk of equipment failure on job sites. For global purchasers, collaborating with such seasoned OEM partners ensures access to superior products designed to withstand the demands of heavy construction operations.

Key Methods For China Top Bearing Shell Factory From Concept to Delivery Your Trusted OEM Partner

| Method | Description | Benefits | Lead Time |

|---|---|---|---|

| Concept Design | Initial design phase for product specifications. | Aligns vision with customer needs. | 2 Weeks |

| Prototype Development | Creating a working model for evaluation. | Early detection of design flaws. | 4 Weeks |

| Material Selection | Choosing appropriate materials for durability. | Optimizes performance and lifespan. | 1 Week |

| Manufacturing Process | Executing production plans for the product. | Ensures cost-effective and scalable production. | 6 Weeks |

| Quality Assurance | Thorough testing of final products. | Guarantees adherence to standards. | 2 Weeks |

| Packaging and Delivery | Preparing products for shipment. | Safeguards products during transit. | 3 Days |

Don't Miss These China Top Bearing Shell Factory Products Sets the Industry Standard

A

Ava Martinez

Great product! After-sales team showed true professionalism and helped with all my queries.

12

May

2025

B

Benjamin Lee

Very pleased with my order. The support team provided expert guidance when needed.

24

May

2025

K

Kevin Lopez

Great quality and efficiency! The customer service team was informative and supportive.

14

May

2025

E

Emma Walker

Impressive all-around! The after-sales service is worthy of praise for their professionalism.

13

June

2025

S

Sophie Day

Exceptional quality! With such professional support, I felt valued as a customer.

12

May

2025

S

Scarlett Reed

Wonderful product! The customer service team really knows how to treat customers right.

22

June

2025

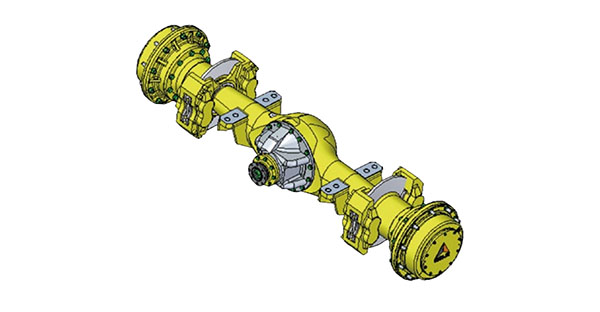

Wheel Loader

Wheel Loader

Excavator

Excavator

Motor Grader

Motor Grader

Backhoe Loader

Backhoe Loader

Road Roller

Road Roller

Spare Parts

Spare Parts