Premium Cat Mini Excavator Parts from Reliable Factory Manufacturers

High-quality replacement parts for your CAT mini excavator are available from Linyi Weiman Import and Export Co., LTD. We offer a comprehensive range of genuine Cat mini excavator parts that ensure optimal performance for your equipment. Our parts are meticulously manufactured to meet the highest standards, guaranteeing a perfect fit and reliable performance. Whether you require hydraulic components, engine parts, undercarriage parts, or other replacements, we are equipped to meet your needs. Designed to withstand the most challenging working conditions, our parts provide the durability and reliability essential for your operations. At Linyi Weiman Import and Export Co., LTD, we prioritize minimizing downtime and maximizing productivity with our extensive selection of Cat mini excavator parts. Trust in our commitment to quality and customer satisfaction for all your equipment needs. Contact us to learn more about our offerings.10 Essential Tips For Cat Mini Excavator Parts Service Pioneers in the Field

When it comes to sourcing parts for Cat mini excavators, understanding the nuances of equipment maintenance is crucial for industry pioneers. As a leading supplier of construction equipment based in Linyi, Shandong province, Linyi Weiman Import and Export Co., LTD emphasizes the importance of high-quality and reliable parts to ensure optimal performance and longevity of these machines. Here are ten essential tips to enhance your parts service strategy.

Firstly, prioritize building relationships with trusted suppliers who understand your specific needs. This relationship can streamline the procurement process, making it easier to obtain the right parts promptly. Secondly, always keep a well-organized inventory of spare parts. This not only prevents downtime but also helps you react swiftly to unexpected repairs. Thirdly, invest in training for your maintenance teams, ensuring they can effectively diagnose issues and recommend suitable parts. Understanding the technical specifications and compatibility of various components is fundamental in avoiding costly errors.

Lastly, staying informed about the latest technologies and advancements in mini excavator parts will give you a competitive edge. As the market evolves, new materials and innovative designs can enhance performance and efficiency. By following these tips, businesses can maximize their investment in Cat mini excavators and ensure they remain pioneers in the competitive construction landscape. Whether you're a veteran in sourcing or new to the field, Linyi Weiman is here to support you with our extensive range of high-quality construction machinery and aftermarket solutions.

10 Essential Tips For Cat Mini Excavator Parts Service Pioneers in the Field

| Tip Number | Tip Description | Importance | Frequency |

|---|---|---|---|

| 1 | Regularly inspect hydraulic components for leaks. | High | Monthly |

| 2 | Clean air filters to ensure optimal engine performance. | Medium | Bi-Weekly |

| 3 | Check and maintain battery connections. | High | Monthly |

| 4 | Lubricate all pivot points to reduce friction. | Medium | Weekly |

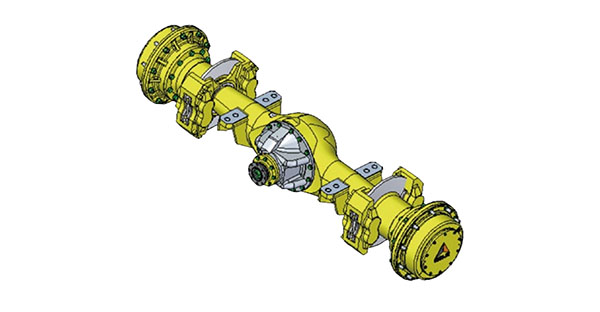

| 5 | Inspect undercarriage for wear and tear. | High | Monthly |

| 6 | Replace worn hoses to prevent failures. | High | As Needed |

| 7 | Check engine oil levels and top up as necessary. | Medium | Weekly |

| 8 | Verify all safety features are operational. | High | Weekly |

| 9 | Maintain cleanliness of the machine and worksite. | Medium | Daily |

| 10 | Train operators on best practices for machine operation. | High | As Needed |

Best Options For Cat Mini Excavator Parts Your Trusted OEM Partner Trusted by Pros

L

Liam Clark

I highly recommend this product. The quality is fantastic and customer care is top-tier!

22

May

2025

H

Harper White

Delighted with this purchase! The quality stands out, and service was efficient and friendly.

17

June

2025

E

Elijah Green

Outstanding product! I was pleased with the professionalism of the customer support team.

14

May

2025

V

Victoria Ramirez

Great product! The service team was professional and genuinely helpful throughout.

11

May

2025

M

Madison Morales

Quality you can rely on! The customer service staff were helpful every step of the way.

03

June

2025

N

Nathaniel Gray

Excellent value for the quality! The support team was knowledgeable and quick to assist.

04

July

2025

Wheel Loader

Wheel Loader

Excavator

Excavator

Motor Grader

Motor Grader

Backhoe Loader

Backhoe Loader

Road Roller

Road Roller

Spare Parts

Spare Parts