China Factory Direct Bushing Bucket Cylinder Supplier - Quality Solutions Await

Are you in need of high-quality bushing bucket cylinders? At Linyi Weiman Import and Export Co., LTD., we specialize in providing top-notch products for wholesale buyers. Our bushing bucket cylinders are meticulously crafted for durability and performance to meet the demands of various industries. As a manufacturer and factory-direct supplier, we focus on your needs, offering competitive pricing without compromising on quality. With extensive market experience, we are dedicated to delivering products that support your business objectives. You can count on us for timely delivery and excellent customer service, ensuring a smooth purchasing process. Our bushing bucket cylinders can enhance your operations and satisfy your customers. Let’s build a profitable business relationship together!Key Methods For BUSHING BUKET CYL Factory For the Current Year

As we venture into a new year, the demand for durable and efficient construction equipment remains crucial for contractors and project managers worldwide. Among the essential components that significantly enhance the performance of heavy machinery are bushings, particularly in applications like bucket cylinders. Understanding the key methods for selecting and maintaining these critical parts can ensure optimal functionality and longevity of your equipment.

One of the primary considerations when sourcing bushings for bucket cylinders is material selection. High-quality bushings made of advanced alloys or composite materials can reduce wear and tear, resulting in less downtime and maintenance costs. Additionally, ensuring the correct sizing and fit is paramount, as improperly sized bushings can lead to misalignment and decreased performance. Collaborating with suppliers who offer customization options tailored to specific machinery can streamline this process and ensure compatibility.

Regular maintenance practices play a vital role in prolonging the life of bushings and the associated machinery. Implementing a routine inspection schedule can help identify wear patterns early on, allowing for timely replacements and adjustments. Furthermore, utilizing premium lubrication systems can minimize friction and enhance the overall efficiency of bucket cylinders. By adopting these methods, global buyers can optimize their procurement strategies, resulting in improved productivity and reduced operational costs in their construction projects.

Key Methods For BUSHING BUKET CYL Factory For the Current Year

| Method | Description | Advantages | Disadvantages | Application |

|---|---|---|---|---|

| CNC Machining | Utilizes computer-controlled machines to manufacture bushings with high precision. | High precision, repeatability, and efficiency. | High initial investment and requires skilled operators. | High-volume production of complex shapes. |

| Injection Molding | Process of injecting molten material into a mold to create bushings. | Can produce large quantities of identical parts quickly. | High mold costs and limited flexibility for changes. | Mass production of standard bushings. |

| Press Fit Assembly | A method of assembling bushings using force to fit them into a housing. | Quick assembly and strong mechanical joint. | Requires precise fit and can lead to material deformation. | Applications requiring strong assembly connections. |

| Forging | Shaping metal using compressive forces to create bushings. | Improves strength and durability of the product. | Requires specialized equipment and can be costly. | Applications where strength is paramount. |

| Casting | Involves pouring liquid material into a mold to form bushings. | Flexible design options and lower costs for complex shapes. | Can result in lower strength and surface finish issues. | Used in customized or small batch production. |

The Ultimate Guide to BUSHING BUKET CYL Exceeds Industry Benchmarks Is The Best

N

Noah Wilson

The item exceeded my expectations in quality. The team was very professional and attentive!

17

June

2025

S

Scarlett Hall

Impressive craftsmanship! The after-sales support team was very helpful and cooperative.

16

May

2025

K

Kevin Lopez

Great quality and efficiency! The customer service team was informative and supportive.

14

May

2025

J

Joseph Bennett

Excellent product! The support staff provided expert advice and support.

21

May

2025

J

Julia Simmons

Incredible quality! I appreciate the professionalism of the after-sales service.

28

May

2025

C

Cora Foster

Very satisfied! The quality is excellent, and the support staff provided real expertise.

17

May

2025

Wheel Loader

Wheel Loader

Excavator

Excavator

Motor Grader

Motor Grader

Backhoe Loader

Backhoe Loader

Road Roller

Road Roller

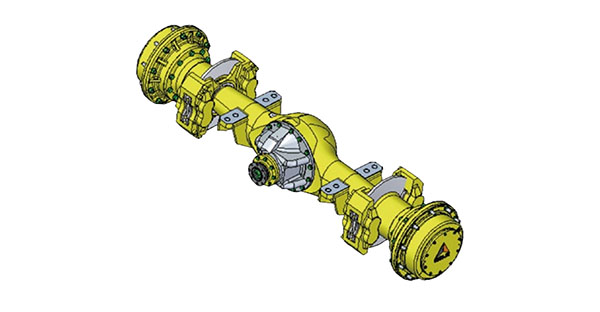

Spare Parts

Spare Parts